The Foundation of Connectivity

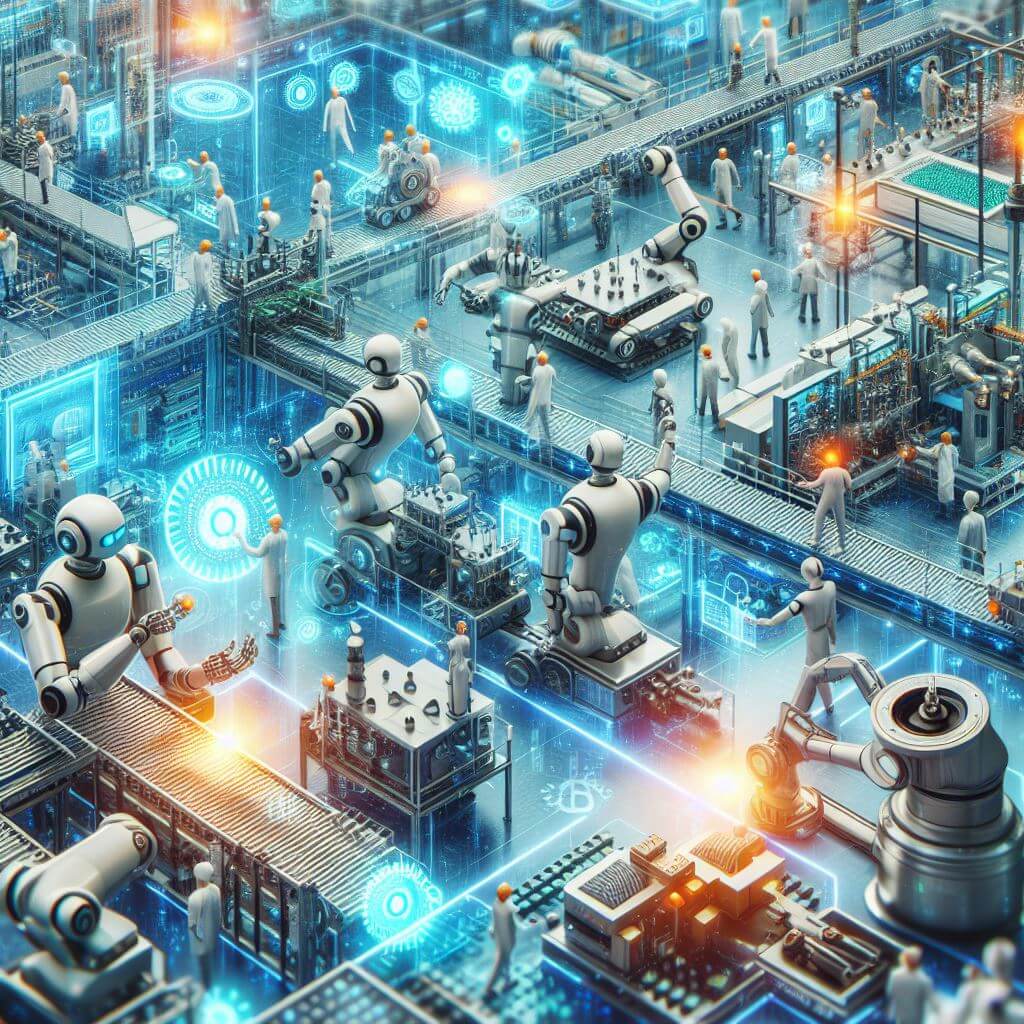

Central to the transformative journey of Industry 4.0 is the unparalleled connectivity established by the synergy between the Internet of Things (IoT) and Machine-to-Machine (M2M) technologies. Picture a factory floor where machines seamlessly communicate with each other in real-time, creating a dynamic network where every component, machine, and process is an integral part of an interconnected web.

This foundational connectivity serves as the backbone of a smart manufacturing environment, ushering in a new era where the exchange of data is not just a feature but a fundamental necessity. The digital threads woven by IoT and M2M form the infrastructure that underpins the efficient functioning of smart factories, facilitating a level of coordination and cooperation among devices that was once unimaginable.

Optimizing Production with Real-Time Data

Imagine a manufacturing environment where every machine, assembly line, and workstation is equipped with sensors that continuously collect and transmit real-time data. This influx of data provides a comprehensive view of the production process, enabling decision-makers to respond promptly to dynamic conditions. With accurate and up-to-the-minute information, manufacturers can make data-driven decisions that streamline operations and boost productivity.

One of the standout features of leveraging real-time data in manufacturing is the adoption of predictive analytics. Advanced algorithms analyze incoming data to foresee potential issues, allowing for proactive maintenance. Instead of reacting to equipment failures, manufacturers can address concerns before they escalate, minimizing downtime, and extending the lifespan of machinery. This predictive approach translates to significant cost savings and a more efficient production cycle.

Real-time data feeds into a continuous loop of process optimization. Monitoring variables such as machine performance, energy consumption, and production rates allows manufacturers to identify areas for improvement on an ongoing basis. By adjusting parameters in real-time, processes can be fine-tuned to operate at peak efficiency. This adaptability is crucial for staying competitive in a fast-paced manufacturing landscape.

In the era of Industry 4.0, maintaining high product quality is paramount. Real-time data from sensors and cameras play a pivotal role in quality control by providing instant feedback on product characteristics. Any deviations from established quality standards trigger immediate corrective actions, ensuring that defects are identified and rectified in real-time. This not only safeguards the quality of the end product but also contributes to a reduction in waste and rework.

The ability to optimize production in real-time facilitates a more agile response to changing market demands. Manufacturers can swiftly adjust production volumes, alter product configurations, or introduce new features based on real-time insights into consumer preferences. This adaptability positions companies to stay ahead in a dynamic market landscape, meeting customer expectations with flexibility and speed.

Predictive Maintenance

Traditionally, maintenance has been a reactive endeavor—fixing equipment when it breaks down. However, this reactive approach comes with significant drawbacks, including unplanned downtime, increased repair costs, and the potential for cascading disruptions throughout the production chain. Predictive maintenance, powered by real-time data from IoT-enabled sensors, revolutionizes this model.

The core principle of predictive maintenance is proactively identifying potential issues before they escalate into critical failures. Sensors embedded in machinery continuously monitor various parameters such as temperature, vibration, and wear, generating a wealth of data. Advanced analytics and machine learning algorithms then sift through this data to detect patterns indicative of impending failures.

Condition-based monitoring, a key aspect of predictive maintenance, involves assessing the health of equipment based on real-time data. By establishing baseline performance metrics, deviations from the norm trigger alerts, signaling that maintenance is required. This condition-based approach enables manufacturers to address issues precisely when needed, eliminating unnecessary preventive maintenance tasks.

The most significant advantage of predictive maintenance is its potential to minimize downtime. By intervening precisely when a component shows signs of deterioration, manufacturers can schedule maintenance during planned downtime, preventing unexpected equipment failures that could disrupt production schedules. This targeted approach maximizes the operational uptime of machinery and minimizes the economic impact of unplanned stoppages.

Predictive maintenance contributes to substantial cost savings over time. By avoiding unnecessary preventive maintenance and reducing emergency repairs, manufacturers can optimize their maintenance budgets. Additionally, the extended lifespan of equipment through proactive care enhances the return on investment, as assets operate at peak efficiency for more extended periods.

The success of predictive maintenance hinges on the effective use of data. IoT sensors generate a constant stream of information, and the analytical tools interpreting this data empower maintenance teams with actionable insights. This data-driven decision-making allows for a more strategic and efficient allocation of resources, ensuring that maintenance efforts are targeted where they will have the most significant impact.

Smart Supply Chains

Smart supply chains prioritize real-time tracking and traceability as fundamental pillars. IoT-enabled sensors and RFID (Radio-Frequency Identification) tags are strategically deployed throughout the supply chain network, providing a continuous stream of data on the location, condition, and movement of goods. This real-time visibility is instrumental in reducing delays, preventing losses, and enabling proactive decision-making.

IoT devices generate an abundance of data that, when harnessed through predictive analytics, becomes a powerful tool for forecasting demand. By analyzing historical data, market trends, and external factors in real-time, smart supply chains can anticipate demand fluctuations. This foresight allows manufacturers to adjust production schedules, optimize inventory levels, and enhance overall responsiveness to market dynamics.

The integration of M2M communication in inventory management transforms static supply chains into dynamic, responsive systems. Automated systems can communicate inventory levels, demand patterns, and consumption rates to optimize stock levels. This ensures that warehouses are well-stocked with the right products at the right time, minimizing excess inventory and reducing carrying costs.

In industries where product quality is paramount, smart supply chains leverage IoT sensors to monitor the condition of goods throughout their journey. From temperature-sensitive pharmaceuticals to fragile electronics, these sensors ensure that products are transported and stored within specified conditions. Any deviations trigger alerts, allowing immediate corrective action to maintain product integrity.

An inherent strength of smart supply chains lies in their ability to proactively identify and address issues before they escalate. Predictive analytics, coupled with real-time monitoring, enable supply chain managers to foresee potential disruptions. Whether it’s rerouting shipments to avoid delays or adjusting production schedules based on demand predictions, these proactive measures enhance overall resilience.

Human-Machine Collaboration

Human-machine collaboration revolves around the seamless integration of automation technologies into manufacturing processes. Machines, equipped with advanced sensors and M2M communication capabilities, handle routine, repetitive tasks with precision and speed. This not only enhances efficiency but also frees human workers to focus on tasks that require creativity, critical thinking, and emotional intelligence.

Human-machine collaboration revolves around the seamless integration of automation technologies into manufacturing processes. Machines, equipped with advanced sensors and M2M communication capabilities, handle routine, repetitive tasks with precision and speed. This not only enhances efficiency but also frees human workers to focus on tasks that require creativity, critical thinking, and emotional intelligence.

Collaborative robots, or cobots, are a prime example of the symbiotic relationship between humans and machines. These robots work alongside human counterparts, assisting with physically demanding or hazardous tasks. With built-in safety features, such as sensors that detect human presence, cobots contribute to a safer working environment, reducing the risk of workplace accidents.

Augmented Reality (AR) is bridging the gap between human capabilities and the vast amount of data generated by machines. In manufacturing, AR provides workers with real-time information, visualizations, and instructions overlaid on their field of view. This not only facilitates training but also augments the skills of workers, enabling them to perform complex tasks with precision.

Human-machine collaboration thrives on data-driven decision-making. Machines equipped with sensors continuously collect and analyze data, providing valuable insights into production processes. Human workers, armed with this data, can make informed decisions, optimize workflows, and contribute to continuous improvement initiatives.

The augmented workforce is inherently flexible and adaptable. Machines can be reprogrammed to handle different tasks, and human workers can acquire new skills to operate and oversee evolving technologies. This adaptability is crucial in an era where market demands, product designs, and production requirements are subject to rapid changes.

Human creativity remains an unparalleled force in the manufacturing realm. By offloading repetitive tasks to machines, human workers can focus on ideation, problem-solving, and innovation. This collaboration fosters a culture of continuous improvement, driving advancements in product design, process optimization, and overall manufacturing innovation.

The integration of machines into the workforce necessitates training and upskilling initiatives. Investing in the development of both technical and soft skills ensures that the workforce remains proficient in operating, maintaining, and collaborating with machines. This proactive approach to skills development future-proofs the workforce against technological disruptions.

Precision and Consistency

One of the primary advantages of IoT and M2M in quality control is real-time monitoring. Sensors embedded in manufacturing equipment continuously collect data throughout the production process. This data is instantly transmitted and analyzed, allowing for immediate identification of any deviations or irregularities. Quick response times enable proactive measures, reducing the likelihood of defective products reaching the final stages of production.

Predictive analytics, powered by the data generated from connected devices, plays a pivotal role in ensuring precision in manufacturing. By analyzing historical data and patterns, machines equipped with predictive analytics algorithms can anticipate potential quality issues before they occur. This proactive approach enables manufacturers to implement preventive measures, maintaining consistent product quality.

IoT sensors are deployed at various points in the production line to capture quality metrics. These sensors monitor factors such as temperature, humidity, pressure, and other critical parameters that can influence product quality. Any deviation from the predefined standards triggers alerts, prompting immediate corrective actions. This level of granularity in monitoring ensures that even subtle variations are addressed to uphold quality standards.

Incorporating automation into inspection and testing processes ensures both precision and consistency. Automated systems equipped with advanced sensors can examine products with a level of detail that surpasses human capabilities. This not only reduces the likelihood of human error but also accelerates the inspection process, contributing to overall production efficiency.

IoT and M2M technologies facilitate end-to-end traceability across the supply chain. Each component or raw material used in the manufacturing process is tagged with unique identifiers that can be tracked throughout the production journey. This traceability ensures that any quality issues can be traced back to their source, facilitating targeted interventions and preventing recurrence.

Machine Learning algorithms, trained on historical quality data, contribute to continuous improvement initiatives. These algorithms can identify subtle patterns and correlations that may escape human observation. By continuously learning and adapting, machine learning models enhance the accuracy of quality predictions and contribute to ongoing efforts to raise production standards.

Energy Efficiency

The deployment of smart sensors is at the core of energy efficiency initiatives. These sensors are strategically placed throughout industrial facilities to monitor energy consumption in real-time. By collecting granular data on usage patterns, companies can identify areas of high consumption and implement targeted strategies for optimization.

Predictive maintenance, a capability enhanced by IoT and M2M, goes beyond preventing machinery breakdowns. By analyzing data from connected devices, predictive algorithms can forecast when equipment is likely to operate less efficiently. This foresight enables proactive maintenance, preventing energy inefficiencies before they occur.

The integration of automation and IoT technologies allows for dynamic energy management. Industrial processes can be optimized in real-time based on energy demand, production schedules, and external factors like weather conditions. Automated systems ensure that energy-intensive operations are executed when electricity costs are lower or when renewable energy sources are most abundant.

IoT-enabled devices are transforming manufacturing processes into energy-responsive entities. Smart manufacturing equipment can adjust their energy consumption based on real-time demand, ensuring that energy is used efficiently. For instance, production lines can automatically slow down during periods of low energy availability, aligning manufacturing output with energy availability.

Incorporating renewable energy sources into industrial setups is facilitated by IoT and M2M connectivity. Smart grids and energy management systems can seamlessly integrate power generated from renewable sources like solar panels or wind turbines. These systems ensure a smooth transition between traditional and renewable energy sources, optimizing energy consumption and reducing reliance on non-renewable resources.

The impact of energy efficiency extends beyond the factory floor. IoT and M2M technologies contribute to the creation of energy-efficient supply chains. Real-time tracking of goods, optimized routing, and smart warehouses powered by these technologies result in reduced energy consumption in logistics and distribution, further contributing to sustainability goals.

Data analytics, driven by the vast amount of information generated by connected devices, plays a crucial role in the continuous improvement of energy efficiency strategies. Analyzing historical data helps identify trends, assess the effectiveness of energy-saving initiatives, and refine strategies for even greater efficiency gains over time.